Hotline

+86 512-81666096209、What is liquid oxygen storage tank? - Doer Equipment

Classification:Forum PublishTime:2023-01-11 13:41:57

What is liquid oxygen storage tank ? - Doer Equipment

Liquid oxygen tank is a storage pressure vessel for storing liquid oxygen, commonly known as liquid oxygen tank. Liquid oxygen tank mainly used for storing liquid oxygen.

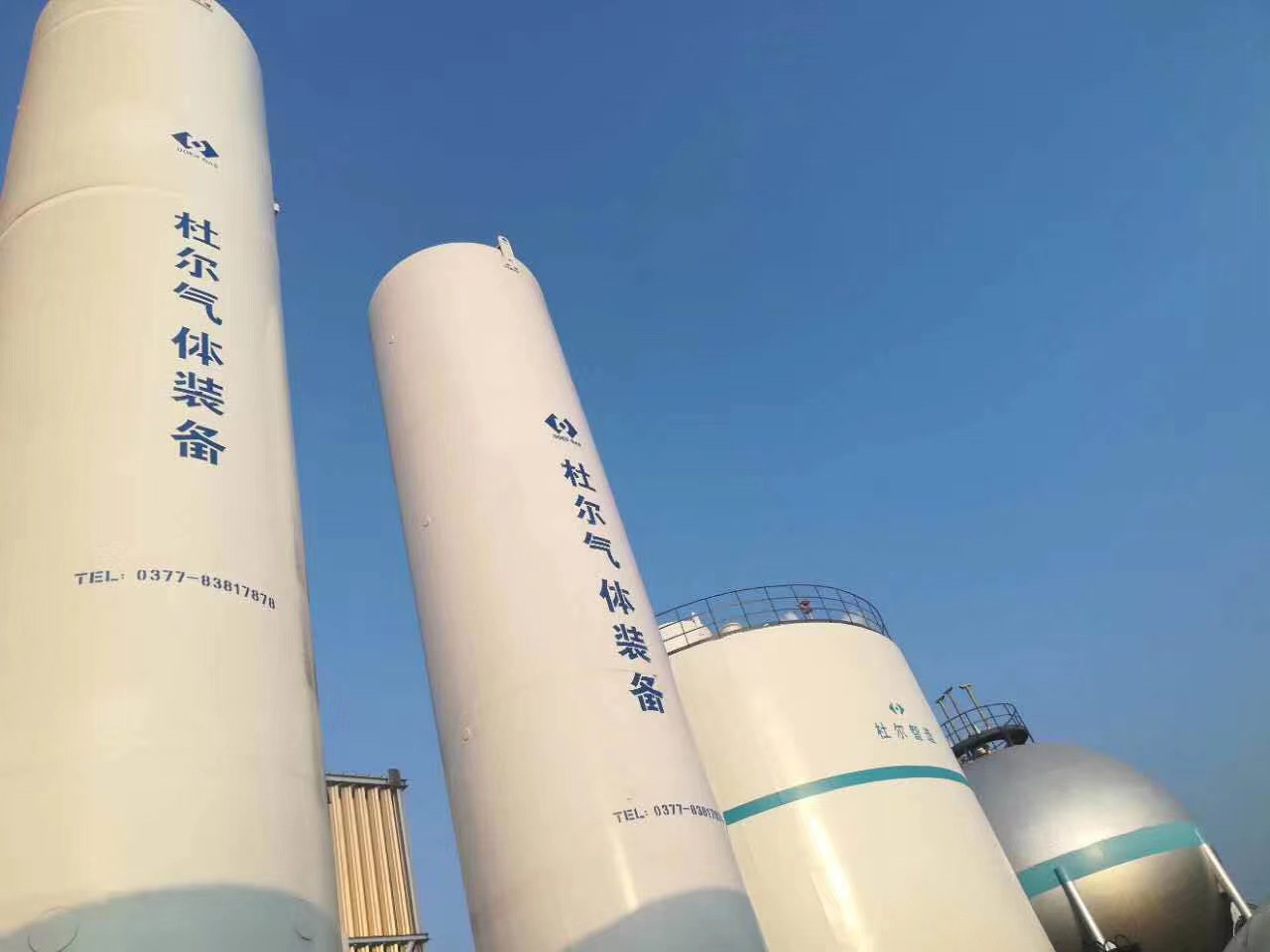

We are specialized in supplying liquid oxygen tanks with complete specifications. We can choose the specifications of liquid oxygen tanks according to different needs. We always regard the quality of liquid oxygen tanks as our life, and always give priority to the quality of our liquid oxygen tanks, with rapid delivery and reasonable price. The company provides the design, development, production and sales of liquid oxygen tanks, equipment and systems, and can design and manufacture all kinds of special low-temperature equipment and systems completely according to customer requirements. The inner liner is made of stainless steel, and the outer liner is made of Q345R. The surface anti-corrosive coating adopts sand blasting, purging, spraying and other processes, and adopts two-component quick-curing liquid coating.

The storage of liquid oxygen must be insulated, so the liquid oxygen tank has a liner, thermal insulation layer (or vacuum layer), and shell. Although there is an insulating layer, the liquid oxygen temperature cannot be maintained. The material of the liquid oxygen tank is thinner, much thinner than the oxygen cylinder, so there must be a vent pipe and valve. After venting, oxygen takes away heat to achieve the purpose of heat preservation. It's like boiling water to keep 100 degrees. But sometimes the heat of liquid oxygen is too little and the pressure in the tank is too low, so there must be a heating circuit and a booster valve. The heating circuit works by convection of liquid oxygen, without pump, as long as external heat is introduced, and the boiling point of liquid oxygen is - 183 ℃. In this way, the liquid oxygen tank is complicated and must have a protective frame, pressure gauge, etc. The safety valve of the liquid oxygen tank can be closed automatically, but the booster valve cannot be closed automatically, which can be used for pressure regulation.

Prev: 208、What are the important functions of vaporizers- Doer Equipment

Next: 210、What should we pay attention to when using liquid argon storage tank- Doer Equipment

News

- 216、Advantages of Double Metal Full Capacity Tank … [2023-05-09]

- 215、Design principles for low-temperature storage … [2023-05-09]

- 214、Low temperature storage tank safety education … [2023-05-09]

- 213、Objectives of project construction management-… [2023-05-09]

- 212、Quality service advantages of Doer large low-t… [2023-05-09]

- 211、Advantages of Doer Large Low Temperature Stora… [2023-05-09]

- 216、Design scope of atmospheric and low-temperatur… [2023-05-08]

- 215、Process flow of low-temperature LNG storage ta… [2023-05-08]

- 214、Testing methods for low-temperature argon stor… [2023-05-08]

- 213、Performance Description of Low Temperature Eth… [2023-05-08]